A car suspension system is a complex arrangement of components designed to provide comfort, stability, and control while driving. It connects the vehicle’s body to its wheels and plays a critical role in absorbing shocks, maintaining tire contact with the road, and ensuring a smooth ride over varying terrains.

Functions of a Suspension System

- Shock Absorption: Dampens vibrations and bumps from uneven road surfaces.

- Road Grip: Ensures consistent tire contact with the road for better traction and handling.

- Stability: Maintains balance and control during cornering, braking, and acceleration.

- Comfort: Provides a smooth ride for passengers by isolating them from road irregularities.

Types of Suspension Systems

Based on Design

- Dependent Suspension

- Description: Both wheels on the same axle are connected, and movement in one wheel affects the other.

- Common in: Heavy-duty vehicles like trucks.

- Advantages: Simpler and durable design, suitable for heavy loads.

- Disadvantages: Less comfort and poorer handling.

- Examples:

- Leaf Spring Suspension

- Solid Axle Suspension

- Independent Suspension

- Description: Wheels on the same axle move independently, providing better ride quality.

- Common in: Most modern passenger cars.

- Advantages: Better comfort, improved handling, and more precise steering.

- Disadvantages: More complex and expensive.

- Examples:

- MacPherson Strut

- Double Wishbone

- Multi-link Suspension

Based on Spring Type

- Leaf Spring Suspension

- Description: Long strips of metal (leaves) are stacked and used as springs.

- Applications: Trucks, older cars, and SUVs.

- Advantages: Durable and handles heavy loads well.

- Disadvantages: Limited comfort and poor adaptability to modern vehicles.

- Coil Spring Suspension

- Description: Helical coil springs absorb shocks and provide flexibility.

- Applications: Widely used in modern cars.

- Advantages: Compact, lightweight, and offers good ride comfort.

- Disadvantages: Limited load-carrying capacity.

- Air Suspension

- Description: Uses air-filled rubber or plastic bags instead of metal springs.

- Applications: Luxury vehicles, buses, and high-end SUVs.

- Advantages: Adjustable ride height and superior comfort.

- Disadvantages: Expensive and requires more maintenance.

- Torsion Bar Suspension

- Description: A steel bar is twisted to act as a spring.

- Applications: Off-road vehicles and trucks.

- Advantages: Compact and durable.

- Disadvantages: Limited flexibility compared to coil or air springs.

Specialized Types

- Hydraulic Suspension

- Description: Uses fluid pressure to adjust and absorb shocks.

- Applications: Sports cars and luxury vehicles.

- Advantages: Precise control and adaptability.

- Disadvantages: Expensive and complex.

- Electromagnetic Suspension

- Description: Uses electromagnets to actively control suspension stiffness.

- Applications: Advanced luxury and sports cars.

- Advantages: Exceptional comfort and handling.

- Disadvantages: High cost and complexity.

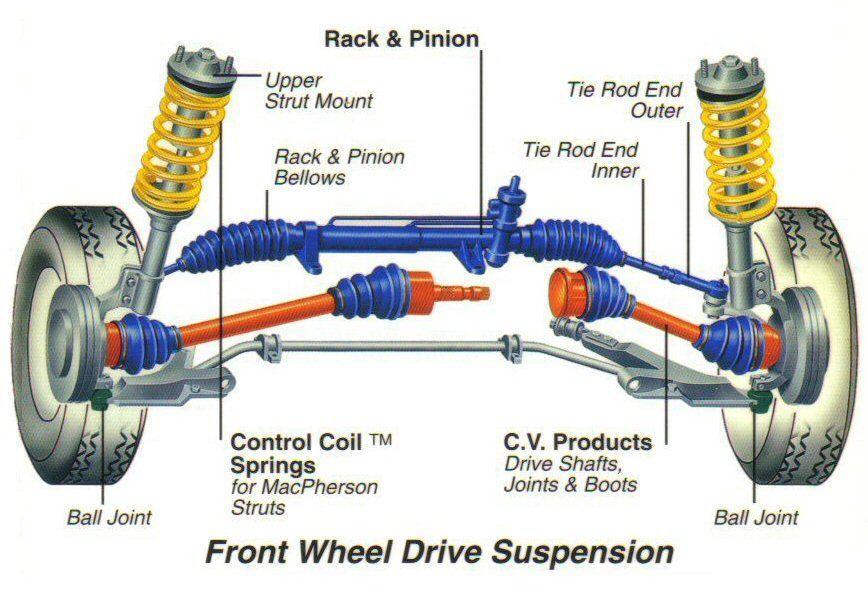

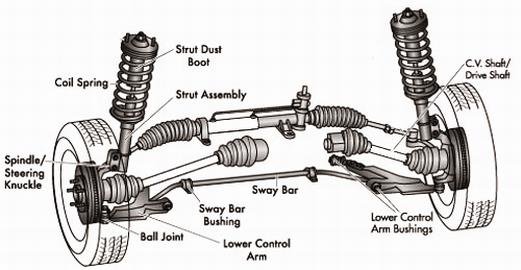

Key Components in Suspension Systems

- Springs: Absorb energy from shocks (e.g., coil springs, leaf springs).

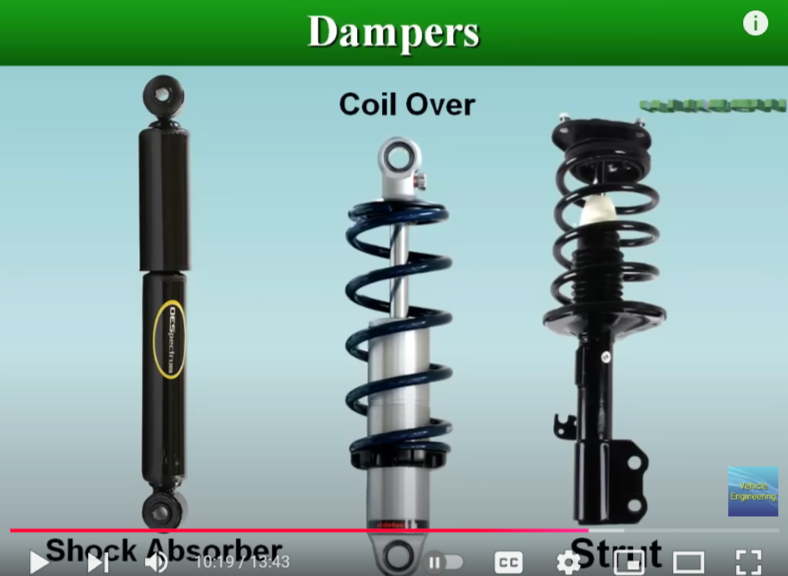

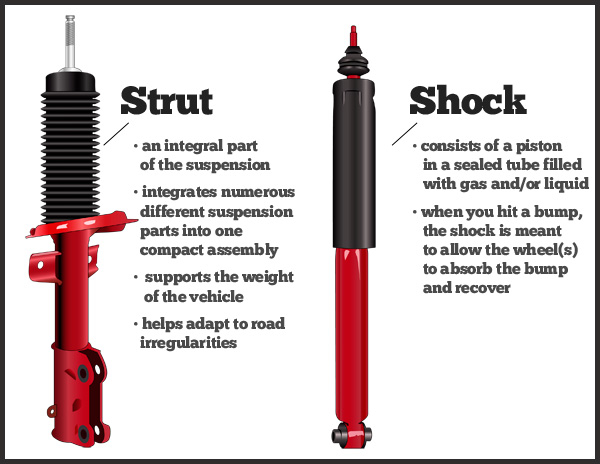

- Shock Absorbers: Control spring oscillations and dissipate energy.

- Struts: Combine spring and shock absorber in one unit.

- Control Arms: Connect the suspension to the vehicle frame.

- Stabilizer Bars (Anti-roll bars): Reduce body roll during cornering.

- Ball Joints: Allow pivoting of control arms for wheel movement.

Maintance parts replace signs

- Your ride is more bumpy than usual

- Your vehicle rocks back and forth when you steer

- Your vehicle feels lower to the ground

- Your tires are wearing unevenly

- Your vehicle rocks or bounces when you brake

- Your vehicle’s struts or shocks are leaking oil

Shocks vs Struts

Shocks, by themselves, have one primary function – to absorb bumps at each wheel – but they are not essential in the operation of a car

Here’s a comparison table highlighting the differences between shocks and struts:

| Aspect | Shocks | Struts |

|---|---|---|

| Definition | A suspension component that dampens spring oscillations and absorbs shocks from the road. | A structural suspension component that combines a shock absorber and a coil spring in one unit. |

| Function | Controls the motion of springs and prevents excessive bouncing. | Provides structural support to the suspension system while controlling spring motion. |

| Structure | Stand-alone component. | Integrated component with both damping and support functions. |

| Role in Suspension | Only dampens vibrations; does not support the vehicle’s weight. | Both supports the vehicle’s weight and dampens vibrations. |

| Complexity | Simpler design; easier to replace. | More complex; harder and costlier to replace. |

| Impact on Alignment | Does not affect wheel alignment. | Directly affects wheel alignment and must be realigned after replacement. |

| Cost | Generally less expensive to replace. | More expensive due to added functionality. |

| Common Applications | Found in vehicles with separate spring and shock systems. | Found in vehicles with MacPherson strut suspension or similar setups. |

| Durability | Typically has a longer lifespan. | May wear out faster due to the combined functions and structural role. |

Key Takeaway:

- Shocks are simpler components focused on damping vibrations, while struts are integral to the suspension system’s structure and require careful handling during maintenance.

car suspension strut wear out

car shock absorbers wear out

shock absorbers can wear out over time, Shock absorbers typically last 50,000 to 100,000 miles, but this can vary depending on how you use your vehicle and the quality of the roads you drive on. Shocks and/or struts look dented or damaged

Price ranges